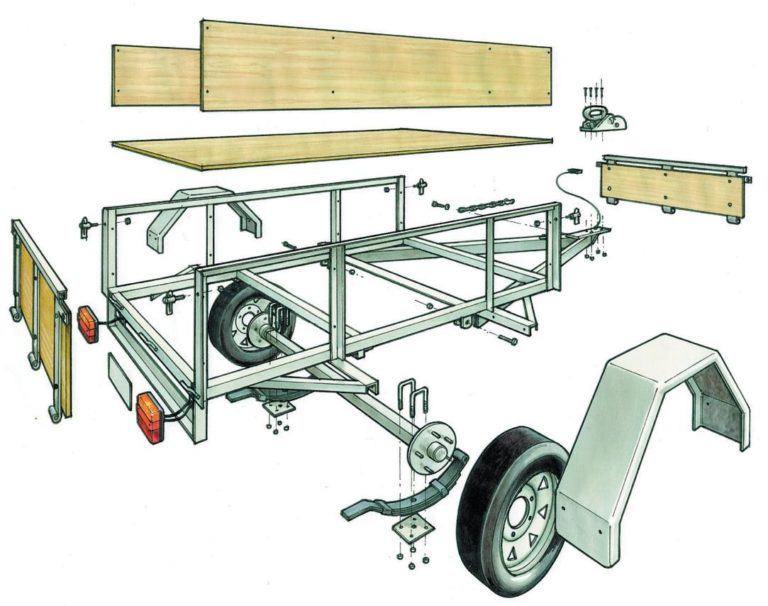

Build a sand trolley

I used a pipe 3200mm long, but it depends on what you have. This is 2400mm along the flat and bent up at the front. The horizontal distance, from the flat to the tip lengthwise, is 340mm. I measured from a square on the pipe, and out 340mm for the bend. The axle is usually 1200mm. I turned a little insert stub axle for putting through the one-inch (25mm) bush in the centre of the wheel and into the axle. You could also turn down the axle to fit. It’s a straight bush because bearings and saltwater don’t mix.